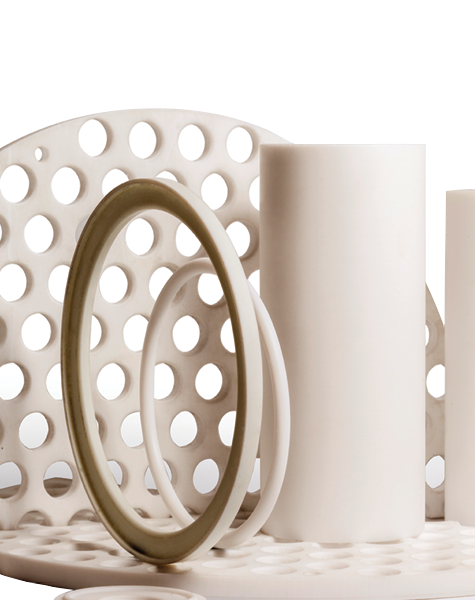

PTFE (Teflon™)

Crossflon® High Performance Engineering Plastics | Beldam Crossley has been at the leading edge of development within the polytetrafluoroethylene industry since its introduction into the UK market in the early 1950s.

By continually developing the exclusive and comprehensive Crossflon® range of specialist compounded materials, such as high performance engineering plastics, we aim to satisfy the ever-increasing demands of today’s industries. Great care is taken in selecting the most suitable polymer to match each requirement.

As part of the Beldam Crossley service, we manufacture a wide range of PTFE products and components to individual customers’ specifications. In addition, with the latest CNC equipment plus a highly skilled workforce, we can produce complex machined, moulded, and fabricated parts in a wide range of sizes.

Our technical department is always available to assist with the design and development of your PTFE parts, especially our Crossflon® High Performance Engineering Plastics

Polytetrafluoroethylene Engineering

Incorporating the most modern fillers, and backed by our ongoing development and test programme, the Crossflon® brand meets the ever increasing requirement for longer life, higher speeds and loads, chemical resistance and cost-effectiveness. Resulting in creating our Crossflon® High Performance Engineering Plastics

PTFE Bellows

Beldam Crossley offers a comprehensive PTFE bellow design and manufacturing service. They are used in many applications and prove effective in reducing vibration transmission, whilst accommodating expansion and contraction in various equipment.

Bearings & Bushes

Providing a range of high quality, UK manufactured Crossflon® Bearings and Bushes. Our range help to combat issues such as poor lubrication, excessive heat and friction water and corrosion issues found with other bearings and bushes.

Lip Seals

Beldam Crossley provides a range of PTFE Lip Seals designed to withstand aggressive environments in the use of rotary applications and equipment, helping to bridge the gap between current technologies for both gas and liquid sealing applications.

Piston Rings

Beldam Crossley PTFE piston rings are manufactured and have been used in oil-free compressors for years. There has been an increase in demand in recent years, with an emphasis on environmental benefits and further cost reduction methods and materials which PTFE Piston rings help to achieve.

Cup Seals

Our cup seals offer a mechanical sealing surface on the edge of hydraulic and pneumatic piston heads, plungers and rams that are useful in applications that have large extrusion gaps, typically lower pressure applications. PTFE Piston cups can include a hole in the centre of the cup and can act as a self-sealing solution.

PTFE / Teflon Seals

Beldam Crossley provides a bespoke PTFE / Teflon seal design facility, providing you with the exact product that matches your specification. We work with multiple grades of PTFE and without experience and expertise can provide an effective, efficient solution to your sealing requirements.

Crossflon® 1110

Inert to most chemicals and is well suited for use in seals exposed to elevated temperatures, high loads or steam contact.

Crossflon® 1403

Reinforced PTFE material providing a good balance of mechanical and tribological characteristics.

Crossflon® 1601

Excellent deformation under load. Good weldability and good resistance to weather and ultra violet exposure.

Machined Component Parts

Beldam Crossley offer a comprehensive range of polymer machining with the ability of machining small to large components with relatively simple to complex features, within a work envelope of 1100mm x 540mm x 480mm. The manufacturing department does not also have the ability of machining components to draw but also provides the service of assembling machined components and purchased parts into sub-assemblies or final assemblies to support the customer’s assembly criteria.

PTFE Bearings

Plane cylindrical and flange type bearings are available in most Crossflon® compounds. Please contact us for us advice on selecting the appropriate material for your application.

PTFE Tape

Most Crossflon® compounds are available in sheet and tape form, which can be etched making them suitable for bonding to other materials or used in a wide range of applications where reduced friction is needed. Compounds specifically formulated with FDA compliant components can be used as non-stick coating surfaces in food and drug contact applications.

WEAR Components

Wear components are available in a wide range of sizes and shapes, other than those indicated above. These include wear strips, pump bodies, and pistons for chemically and thermally demanding operating conditions. We can manufacture to customer specifications or provide design assistance. Please contact us for more information.

PTFE Moulded Rod and Tube

Moulded rods and tubes are available in most Crossflon® compounds. Please contact us for more information on the range.

Formed Parts

We offer hot or cold formed parts in most Crossflon® compounds. Please contact us to discuss your requirement.

Rings

Solid and split pistons rings with a wide range of joint configurations can be manufactured to customer specifications. Alternatively, we can assist in designing a ring to meet with your individual requirements.

Contact Us for Crossflon® High Performance Engineering Plastics

For more information on our Crossflon High Performance Engineering Plastics please contact us!

Feel free to us any question regarding our Crossflon High Performance Engineering Plastics

PROCESSES

Automatic Moulding

Compression Moulding

Machining

Skiving

Stamping

Forming

Etching