Cord Seals (also known as rope seal) offers designers and engineers the ability to increase operating efficiencies by reducing hot gas leakage between components in aircraft engines, other turbines and high-temperature static sealing applications.

The seals are designed to operate over multiple thermal and mechanical cycles, whilst also accommodating differing rates of expansion due to temperature between dissimilar components. The standard design is manufactured to locate into an O-ring type groove – other innovative seals can be designed for use in differing applications.

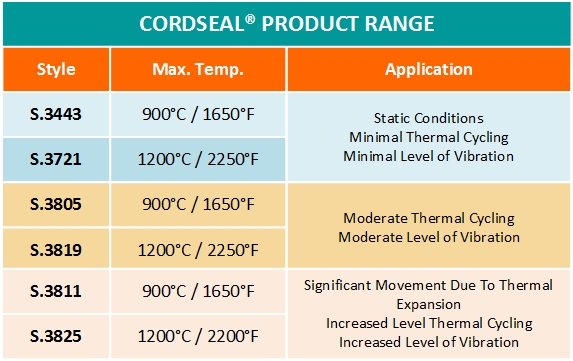

Supporting the need for elevated operating temperatures, the seals have been developed to operate continuously up to of 1200°C (2220°F).

Pilot® High Temperature Cord Seals Applications

- All gas turbine engine applications

- High temperature exhaust systems

- Plus, other high temperature applications

- Reduces gas flow between machined or cast surfaces during thermal cycling

- Can act as a flexible joint.

Installation Styles

Cord seal can be supplied in three different styles:

- 100ft (30m) spooled lengths, allowing cutting to length on site

- Cut lengths to meet customer specifications to allow instant installation on site

- Endless rings for easy installation on-site, reducing gas flow further by eliminating leakage where cord seal ends meet.