Beldam Crossley provide a range of Crossflon® Bearings & Bushes helping to overcome the problem of poor lubrication, excessive heat and cold, friction, water and corrosion issues found with other bearings and bushes. These issues can slow down your process, create waste and add unneccassary time delays.

Contact Beldam Crossley

Contact Beldam Crossley for more data on any of these products using the buttons underneath.

Rulon equivalents – Bearings & Bushes

Take a look at the Rulon equivalents that Beldam Crossley have manufactured here is the UK. Get in touch with us about any of our specialist Bearings & Bushes materials.

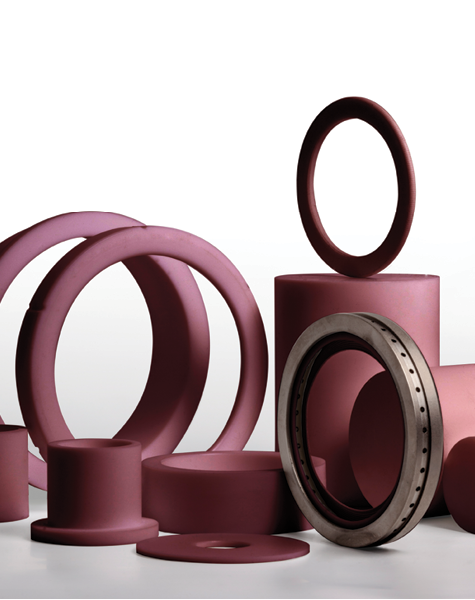

Crossflon LDR5

Maroon colour, ideally suited to rotary and linear bearing applications.

Equivalent to the Rulon LR.

- Highly resistant to wear and creep

- Good dielectric properties

- Good chemical resistance

- Compatible with most hardened steel surfaces

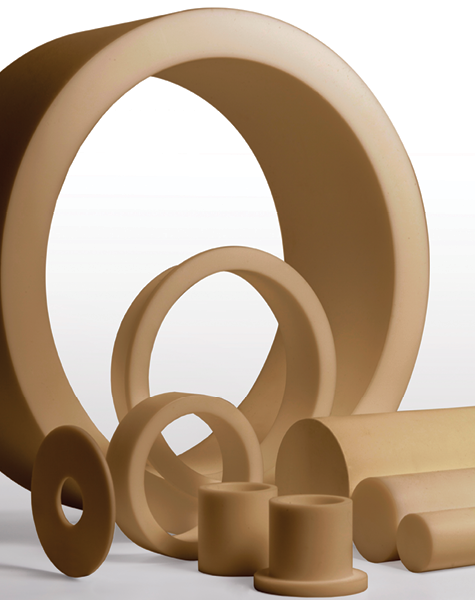

Crossflon J

Gold in colour Specifically formulated with no hard or abrasive filters.

Equivalent to the Rulon J.

- Low coefficient of friction

- Good creep resistance

- Compressive strength

- Very low wear rates compared to unfilled PTFE.

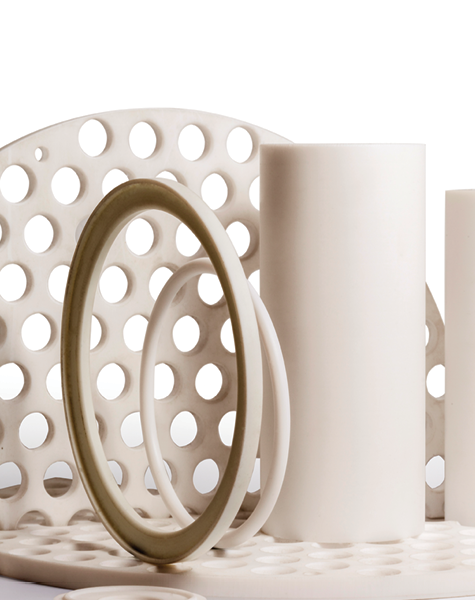

Crossflon FG

White in colour, primarily used in the manufacture of bearings.

Equivalent to the Rulon 641.

- Works very well against soft mating surfaces

- Specifically formulated for use in food and drug applications.

- All materials FDA compliant.

Crossflon® Bearings & Bushes Advantages

Crossflon® Bearings & Bushes Advantages

✔ Simplifies design problems.

✔ Greater reliability.

✔ Improved efficency and performance.

✔ Reduced maintenance and increased service life.

✔ Self lubrication.

✔ Low friction coefficient.

✔ Chemical resistance upon application.

PTFE Design

Beldam Crossley can create PTFE products to your specification, creating a product with the correct PTFE grade material that works best for your application.

Contact our team of design engineers with your requirements and see how we can help you.

Crossflon®

Beldam Crossley has been moulding PTFE for over half a century. We have since developed a wide range of High Performance Crossflon® materials, each suited to a specific application.

Contact us, for more details