What Are Lip Seals and How Are They Used?

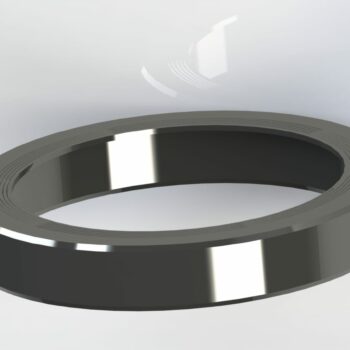

At Beldam Crossley we produce bespoke Lip seals considering seal design along with material selection. It utilises our extensive range of propitiatory PTFE recipes.

They are common in a wide variety of industries: Chemical, Marine, Automotive, Aerospace, Motorsport and Green energy predominantly the Wind turbine industry. Applications vary from pistons, pumps and valves to application within a wind turbine nacelle.

A lip seal is a dynamic seal but will typically seal a rotary shaft. They have long been manufactured using elastomers. Beldam Crossley’s designs push the boundaries of the common elastomer seal by using PTFE. PTFE’s inherent properties such as low and high temperature capability (-250˚C to 260˚C), media compatibility and greatly reduced friction properties allowing systems to run cooler, faster and therefore more efficient.

Lip seal designs can be self-energising as a result of the in-built design characteristics and/or additional energising in the form of springs or steel reinforcement.

The purpose of a lip seal is to retain lubricant in the area it’s required and prevent external contamination. For example, the chemical industry utilises the chemical resistance of PTFE. This is done to seal a variety of pumps and valves throughout their processing lines preventing costly contamination within their processes.

In the renewable market particular wind turbines, Lip seals are used throughout the turbine nacelle. They are used within the drive chain and the connecting equipment. For example Beldam Crossley’s have designed and manufactured a gearbox seal. This is done to contain synthetic oil running at 2-3m/s at ambient temperature.

Benefits include seen the extended life of the seal in comparison to the elastomer versions. This is due to the low coefficients of friction and thermal dissipating properties of our PTFE.